Jetting Assemblies

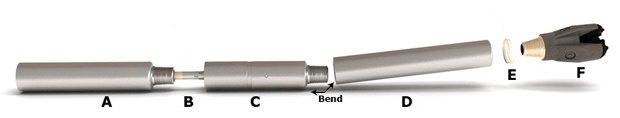

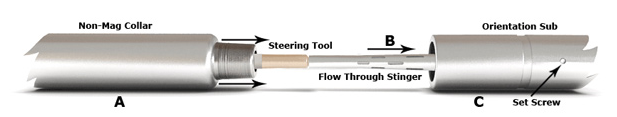

Jetting assemblies are used to provide directional capabilities through a variety of soils. They allow the driller to push the drill string resulting in a direction change due to the geometry of the assembly. Jetting assemblies usually require a number of components and are customized for the rig and project. The O.D. and thread connections of the components should match that of the drill string. SlimDril rents and sells complete assembly or the individual components. A standard jetting assembly consists of :-

Note: if using walkover system just the bent sub forward is required.

| Typical Size Jetting assemblies | ||

| Diameter (OD) | Bend Angle available | Bit Sizes available |

| 4 1/8″ | 1.75/2.00 Degree | 4 3/4″ – 5 1/2″ |

| 4 3/4″ | 1.75/2.00 Degree | 6 1/2″ |

| 6 3/4″ | 1.75/2.00 Degree | 8 1/2 – 9-7/8″ |

| 8″ | 1.75/2.00 Degree | 9 7/8″ – 12 1/4″ |

| Custom Made assemblies available | ||

SlimDril also offer a full range of “Shark head” jetting tools with changeable plates that can be used to adjust the aggressiveness of the steering in softer formations.